(Apply for torque display series)

- Whole series use brushless motor, no carbon pollution, and low noise motor operation. It is the best fit for assembling power torque products.

- Assemble large-sized LED/LCD panel and home appliances. Tools can be hanged with spring balancer to lessen work fatigue.

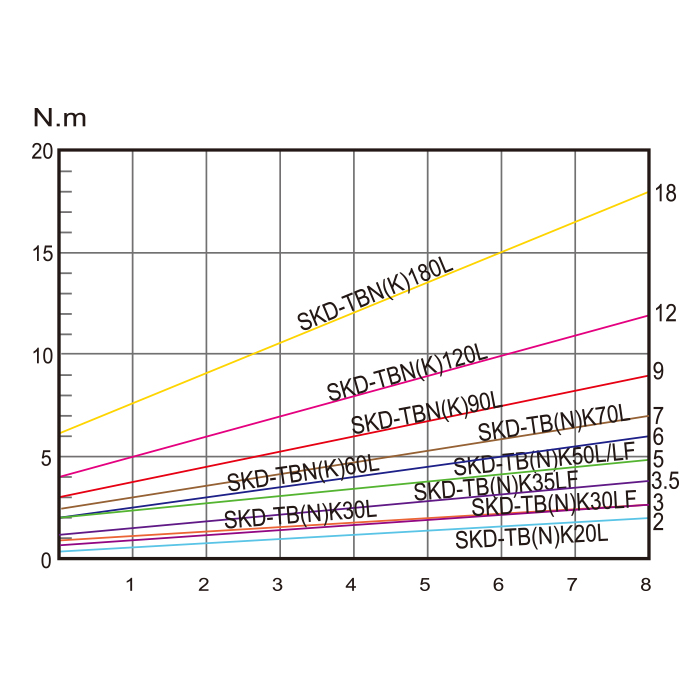

- SKD-TBN(K) series torque range can reach up to 0.3-18 N.m; SKD-TBN(K) series torque range can replace pneumatic screwdriver to avoid unstable torque due to the fluctuation of the air pressure. Also can prevent oil and noise pollution and achieve energy saving and more Eco-friendly.

- SKD-TBN(K) series can be equipped with side handle, which can increase stable torque output, torque precision, and easier for user to operate.

- Suitable for assembling large-scale work pieces in semi-automatic or full automatic assembly line. In particular, the most suitable for applications such as automotive industrial parts assembly, air conditioning, electricity, telecommunications, large appliances and medical equipment assembly.

- Highly mobility, easy to operate, stable torque, high efficiency. Motor can be free from fatigue under long-working hours.

|

|

|

|

Product Specifications

Product Specifications

| Model | SKD-TBK20L SKD-TBNK20L |

SKD-TBK30L SKD-TBNK30L |

SKD-TBK50L SKD-TBK50L |

SKD-TBK30LF SKD-TBNK30LF |

SKD-TBN35LF SKD-TBNK35LF |

SKD-TBN50LF SKD-TBNK50LF |

SKD-TBN70L SKD-TBNK70L |

SKD-TBN60L SKD-TBNK60L |

SKD-TBN90L SKD-TBNK90L |

SKD-TBN120L SKD-TBNK120L |

SKD-TBN180L SKD-TBNK180L |

|

| Input Voltage | DC40V | DC40V | ||||||||||

| Power Consumption | 50W | 50W | 50W | 50W | 50W | 50W | 50W | 100W | 120W | 120W | 200W | |

| Torque(N.m) | Hard Joint | 0.3~2.0 | 0.8~3.0 | 2~5 | 1~3 | 1.2~3.5 | 2~5 | 2.5~7 | 2~6 | 3~9 | 4~12 | 6~18 |

| Soft Joint | 0.3~1.6 | 0.8~2.4 | 2~4 | 1~2.4 | 1.2~2.8 | 2~4 | 2.5~5.6 | 2~4.8 | 3~7.2 | 4~9.6 | 6~14.4 | |

| Repeatable Torque Accuracy(%) | ±5% | ±5% | ||||||||||

| Torque Adjustment | Stepless | Stepless | ||||||||||

| Free Speed(r.p.m) | HI | 1200 | 1200 | 700 | 3300 | 1700 | 1000 | 850 | 1000 | 800 | 550 | 350< |

| LO | — | — | — | — | — | — | — | — | — | — | — | |

| Screw Size Dia(mm) | Machine Screw | 2.3~3.5 | 2.6~4.0 | 4.0~5.0 | 2.0~4.0 | 2.6~4.0 | 4.0~5.0 | 5.0~6.0 | 4.0~5.0 | 5.0~6.0 | ≦8 | ≦10 |

| Tapping Screw | 2.3~3.0 | 2.6~3.5 | ≦4 | 2.0~3.5 | 2.6~3.5 | ≦4 | ≦5 | ≦4 | ≦4.5 | ≦6 | ≦8 | |

| Weight(kg) | 0.7 | 1.2 | ||||||||||

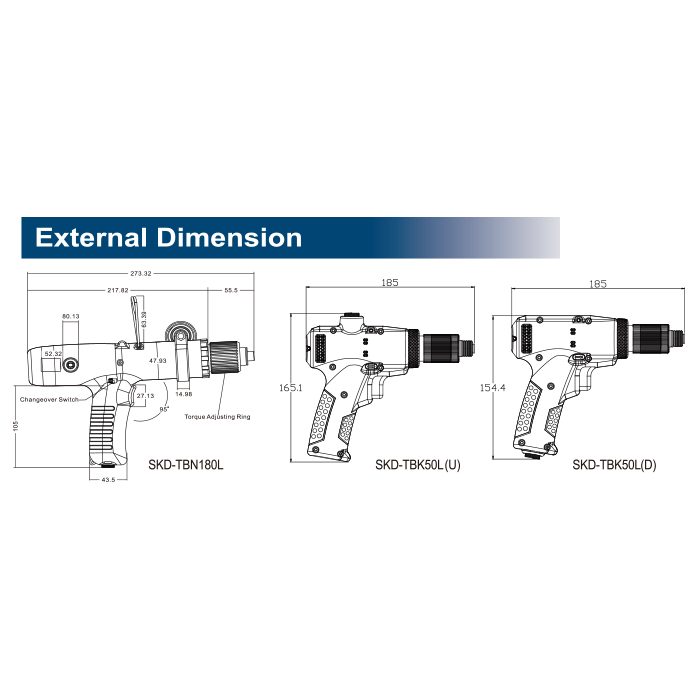

| Length(mm) | 185X150 | 274X160 | ||||||||||

| ESD(Anti-Static) | — | — | ||||||||||

| CE | V | V | ||||||||||

| RoHS | V | V | ||||||||||

| Auxiliary Arm | — | — | ||||||||||

| Handle Grip | — | V | ||||||||||

| Power Controller | SKP-40B-HL(N) | SKP-40B-HL-800 | SKP-40B-HL-800 | |||||||||

| Bit Type |  |

|

|

|||||||||